ZEISS

ZEISS SPECTRUM

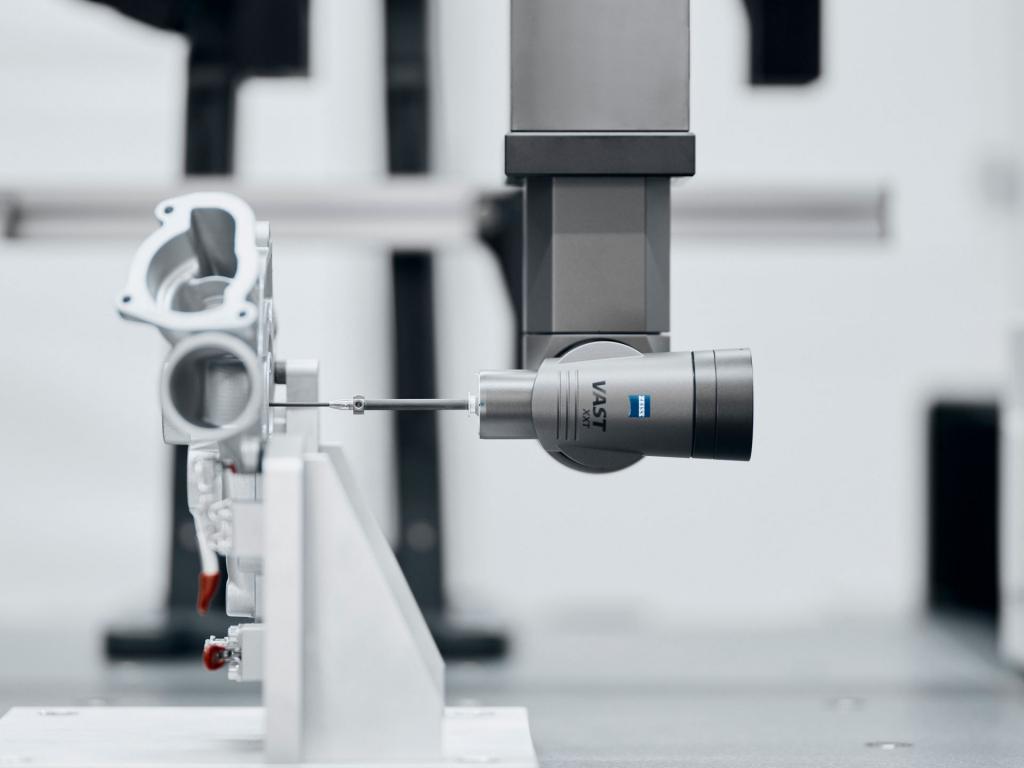

Tactile and optical scanning

ZEISS SPECTRUM offers a wide range of optical and tactile scanning sensors for measuring parts with varying geometries and surfaces. This provides flexible quality control and consistent product results, instilling confidence in measuring results.- Increased measuring volume with VAST XXT compact design

- Optimal price-performance ratio

- Flexibility in sensor selection

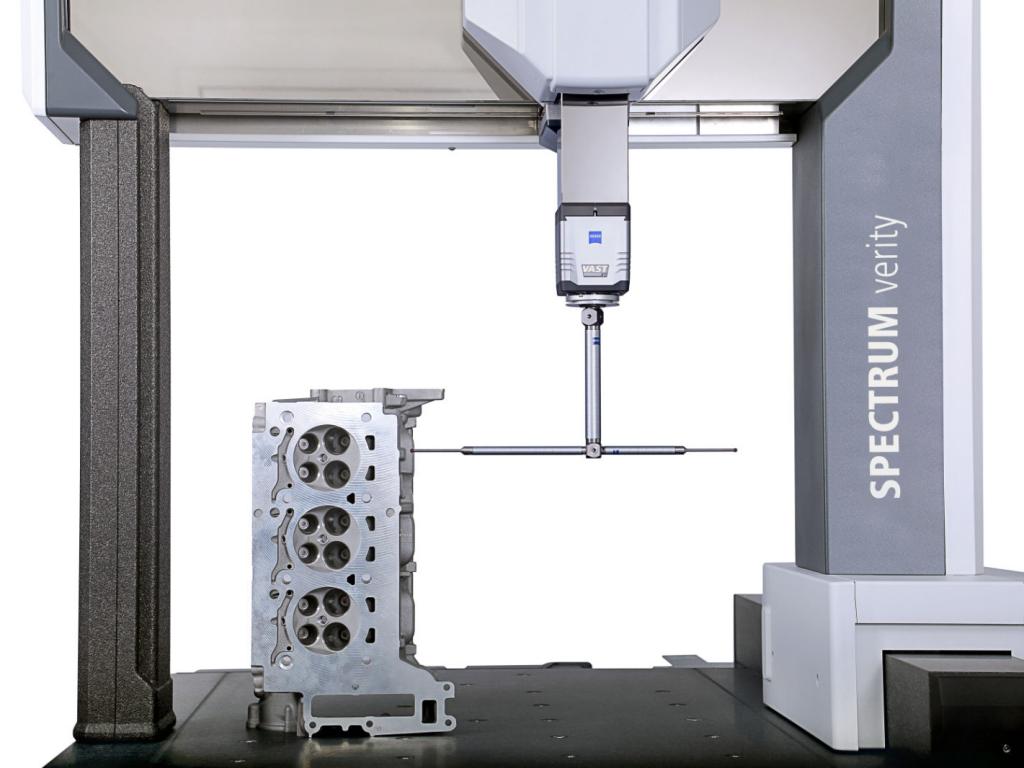

ZEISS SPECTRUM verity

This bridge-type coordinate measuring machine provides great accuracy values and sensor flexibility. Benefit from advanced technology, efficient processes, active scanning as well as highly accurate measurement results for a range of parts and applications. In addition to reliable tactile measurements, ZEISS SPECTRUM verity offers optical scanning through its compatibility with our new laser scanner LineScan One. Optical scanning is a highlight in this class, offering an excellent price-performance ratio.

- Tactile and optical scanning

- Active scanning with ZEISS VAST XT gold

- SoftTouch Mode for increased efficiency

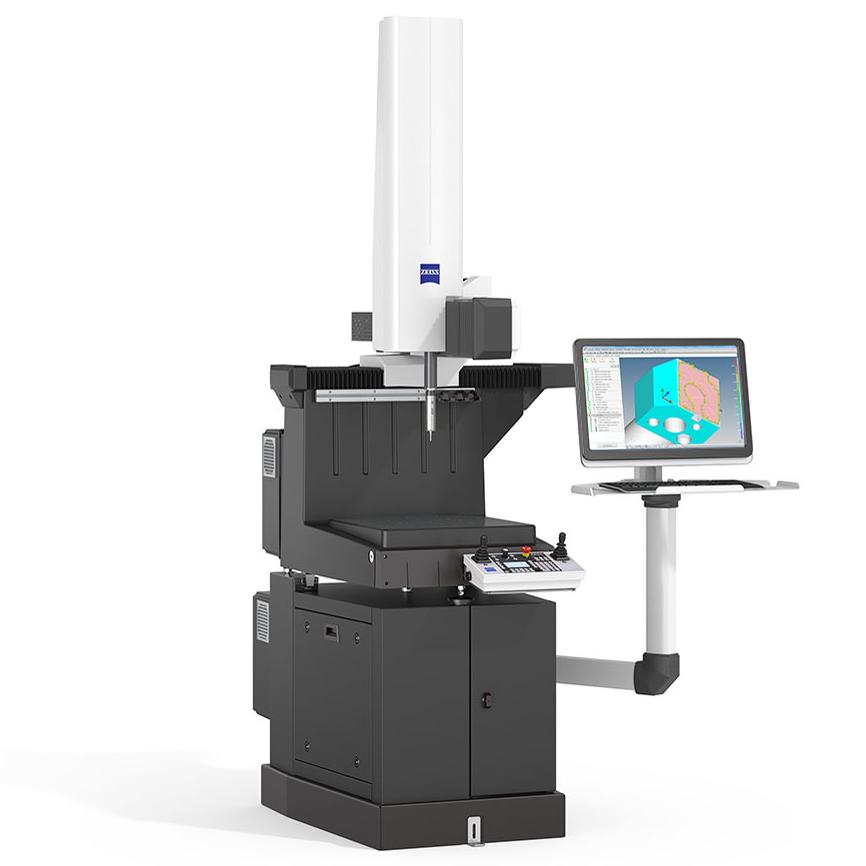

ZEISS CONTURA

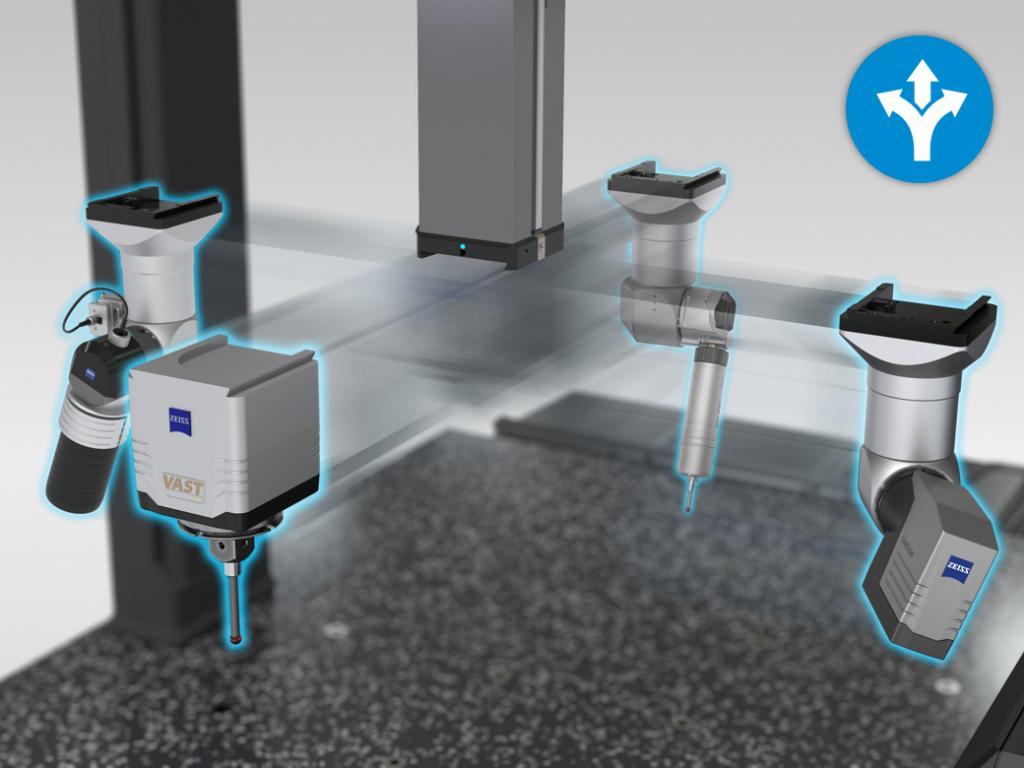

Prepared for all challenges - today and tomorrow

ZEISS CONTURA enables you to be prepared today for the measurement requirements of tomorrow: The new generation is equipped with the mass technology and, thanks to a common interface, enables simple switching between different sensor technologies in just a few simple steps. In addition to innovative options such as measuring in four axes using a flexible rotary table, an automated probe changing system or the HTG option (for larger temperature ranges), the device also stands for first-class performance, ergonomics and future security.

- Versatile sensor technology for diverse applications

- Enhanced measuring speed with reliable accuracy

- Designed for ergonomic comfort and space optimization

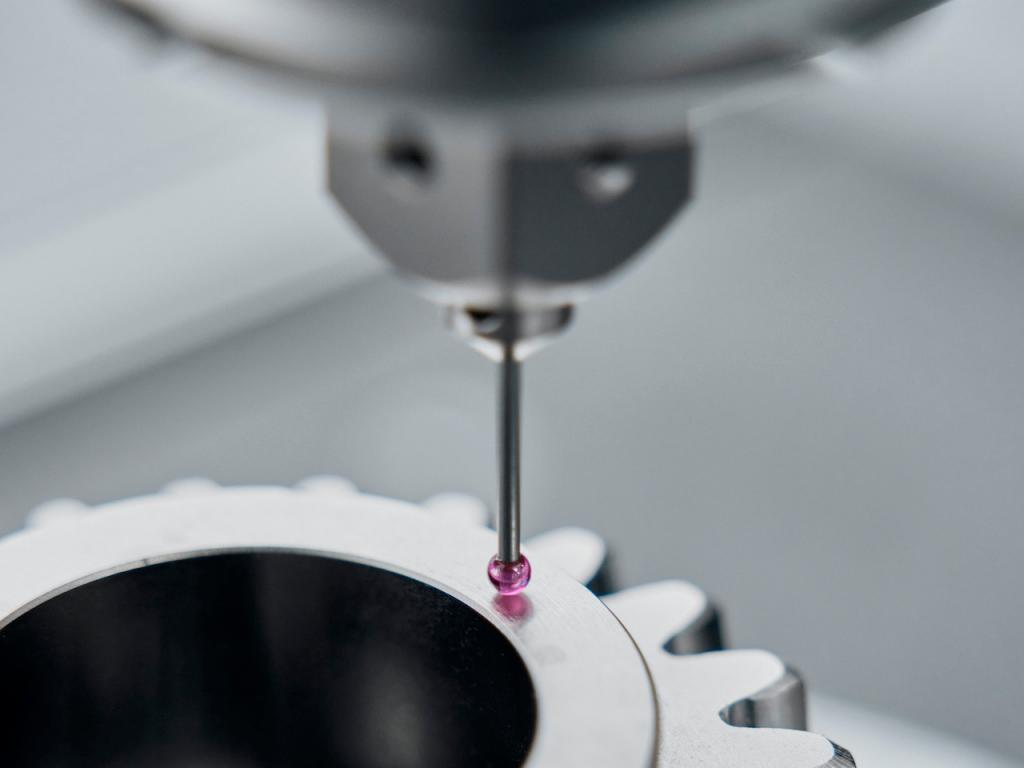

ZEISS MICURA

Maximum precision for small components

ZEISS MICURA defines the standard in precision for compact workpieces and combines advanced technologies such as the ZEISS VAST XT gold active scanning probe, ZEISS VAST XTR gold, navigator technology, and new innovative CMM corrections for unmatched accuracy in its class.

- Highly precise with an accuracy of 1µm

- Active scanning and navigator technology

- High stability due to air bearing

- Optional rotary table for more flexibility with 4-axis scanning

ZEISS PRISMO family

ZEISS PRISMO

With a length measurement error from 0.9 + L/350 µm, ZEISS PRISMO is the flagship among ZEISS CMMs and offers maximum productivity and outstanding performance.

ZEISS PRISMO verity

ZEISS PRISMO verity delivers results with a length measurement error from just 0.7 + L/400 µm and impresses with improved form measurement values.

ZEISS PRISMO ultra

With a length measurement error of 0.5 + L/500 µm, ZEISS PRISMO ultra improves precision even further and is therefore particularly suitable for research and calibration tasks, as well as reference laboratories.

ZEISS PRISMO fortis

ZEISS PRISMO fortis is designed for use in production environments and offers maximum precision even at temperatures of up to 40°C.

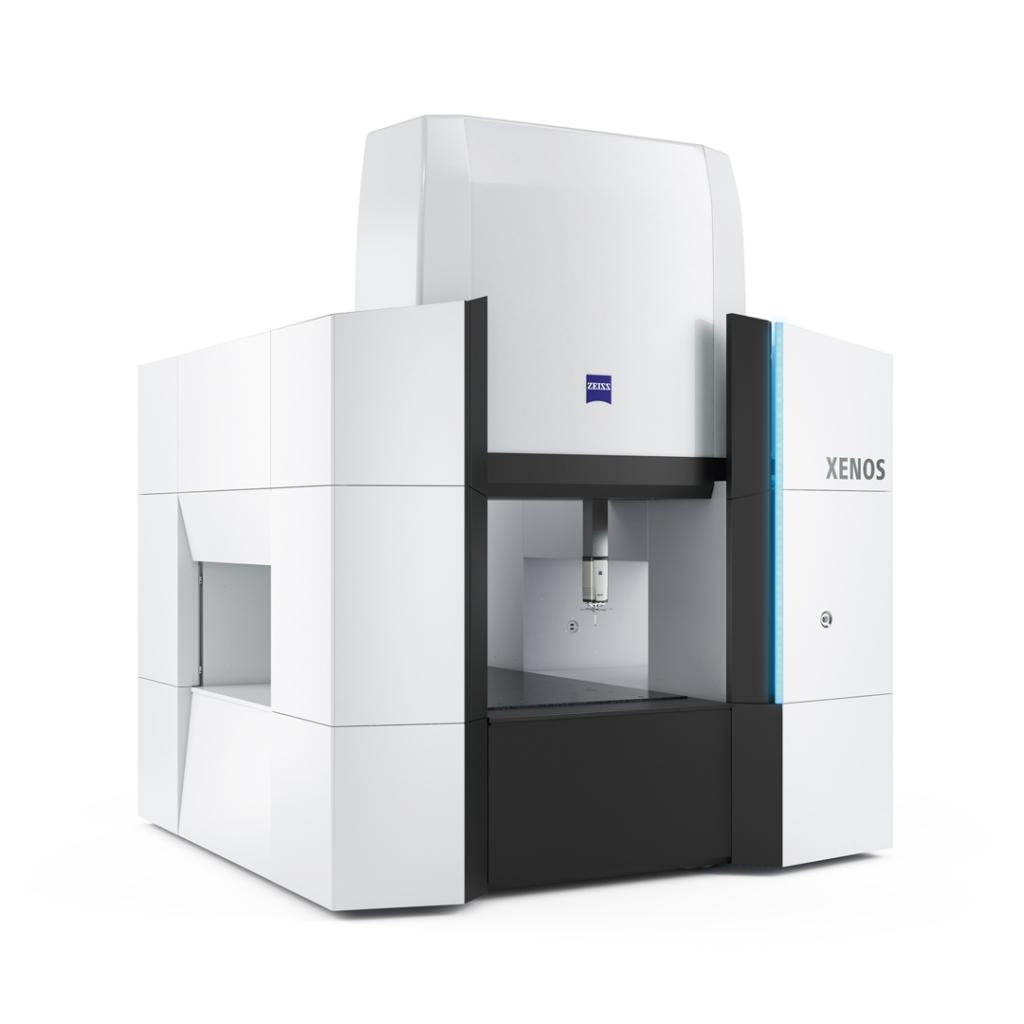

ZEISS XENOS

High-end measuring machine for maximum precision

ZEISS XENOS is at home wherever maximum precision is demanded – in the measuring labs of research institutes, the aerospace industry and the optical industry. The high-end machine combines precision at the limits of what is technically feasible with a measuring range of nearly one cubic meter.

- Unmatched precision with accuracy from 0,2 + L/1000 µm

- Innovative materials for thermal stability and rigidity

- Advanced mechanical design for consistent measuring precision

Large CMM

ZEISS MMZ

Compact solution for large volume parts. ZEISS MMZ is suitable for workpieces up to 5 tons and applications requiring accurate contact measurements with highest precision using ZEISS VAST XT gold.

- Stable design for high performance

- Safety laser scanners

- Flexible and sustainable system

- Pneumatic vibration insulation – no foundation needed

Shop Floor CMMs

ZEISS DuraMax

The natural choice for the shop floor. ZEISS DuraMax combines robustness, precision, and efficiency, making it ideal for at-line measurement in production environments. Resistant to harsh conditions, it supports fast tactile and scanning measurements.

- Robust design for production environments

- High precision under variable conditions

- Advanced scanning technology

X-Ray Systems

ZEISS BOSELLO (2D X-Ray)

Turning inspection into productivity. ZEISS BOSELLO OMNIA is ideal for harsh production environments with automatic defect recognition and 100% in-line inspection.

- Fast 100% in-line inspection of castings

- Pallet loading system for parallel changing and loading

- Optimized for fully automated inspection

ZEISS METROTOM (3D X-Ray)

One CT system for many applications. ZEISS METROTOM provides advanced CT technology for flaw detection and internal measurement with high accuracy.

- High-speed scanning

- Detailed CT image quality

- Accurate metrology (VDI/VDE 2630 1.3)

- Optional DAkkS certification

Contour Measuring System

SURFCOM NEX

ZEISS SURFCOM NEX offers maximum flexibility for contour and surface measurements with interchangeable tactile and optical sensors.

- Future-proof flexibility with multi-sensor capability

- Different granite table and column sizes available

- Optional CNC kit for fully automatic measurements

- Optional topography measurements

Form Measuring System

RONDCOM

RONDCOM systems are designed for large measuring ranges and heavy workpieces, delivering excellent rotational accuracy with reduced measuring times.

- High rotational accuracy

- Reduced measuring times

- Reliable results

Roughness Measuring System

SURFCOM TOUCH

Intuitive surface texture measurement solution for various workpieces with user-friendly operation and quick reporting.

- Intuitive and easy-to-use

- Multiple variations available

- Quick print of results

HANDYSURF

A mobile surface roughness instrument with sleek design, ideal from incoming goods to final inspection.

- Easy-to-use, portable solution

- Sleek and compact design

- Resolution up to 10 nanometers