SERVICES

CMM Measurement Services

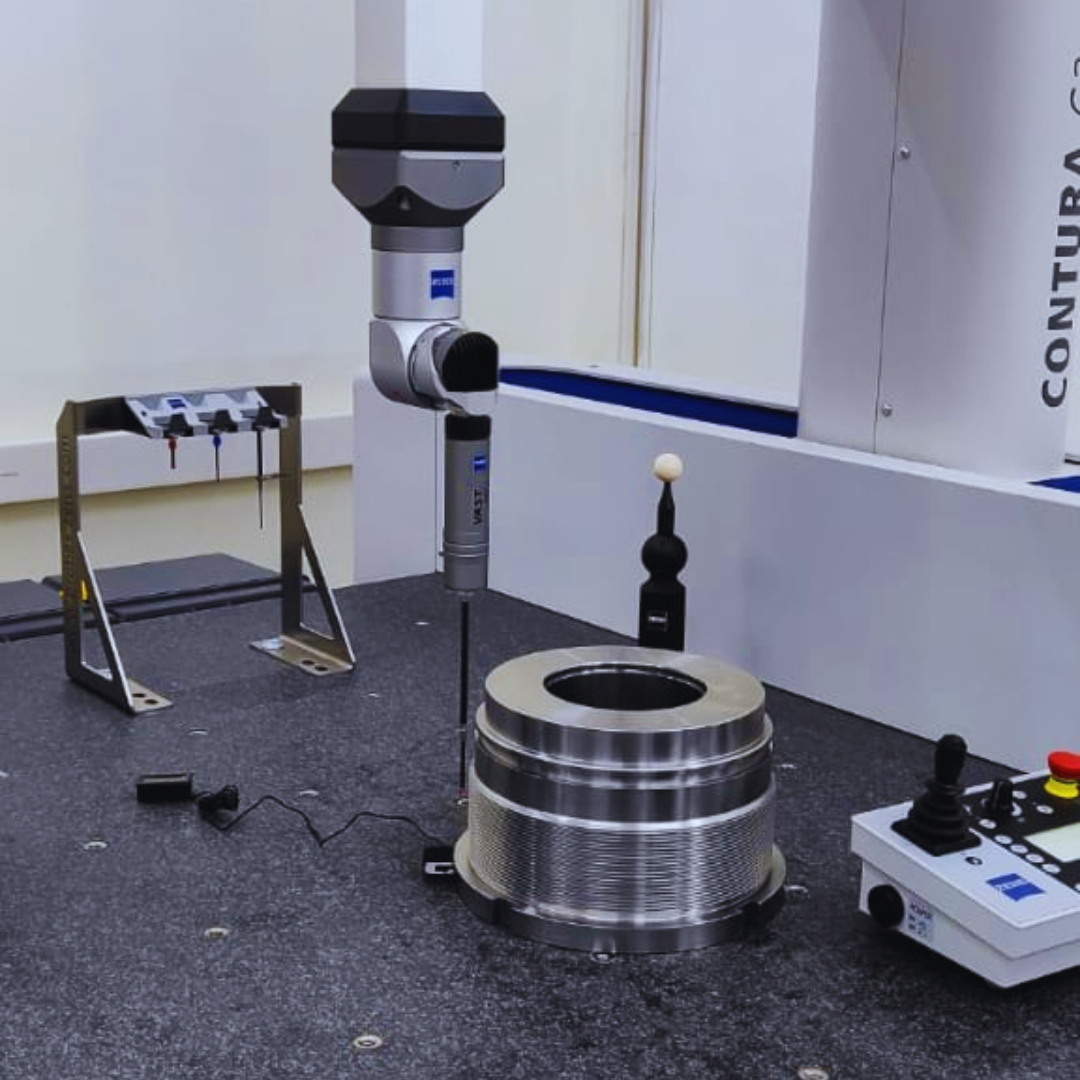

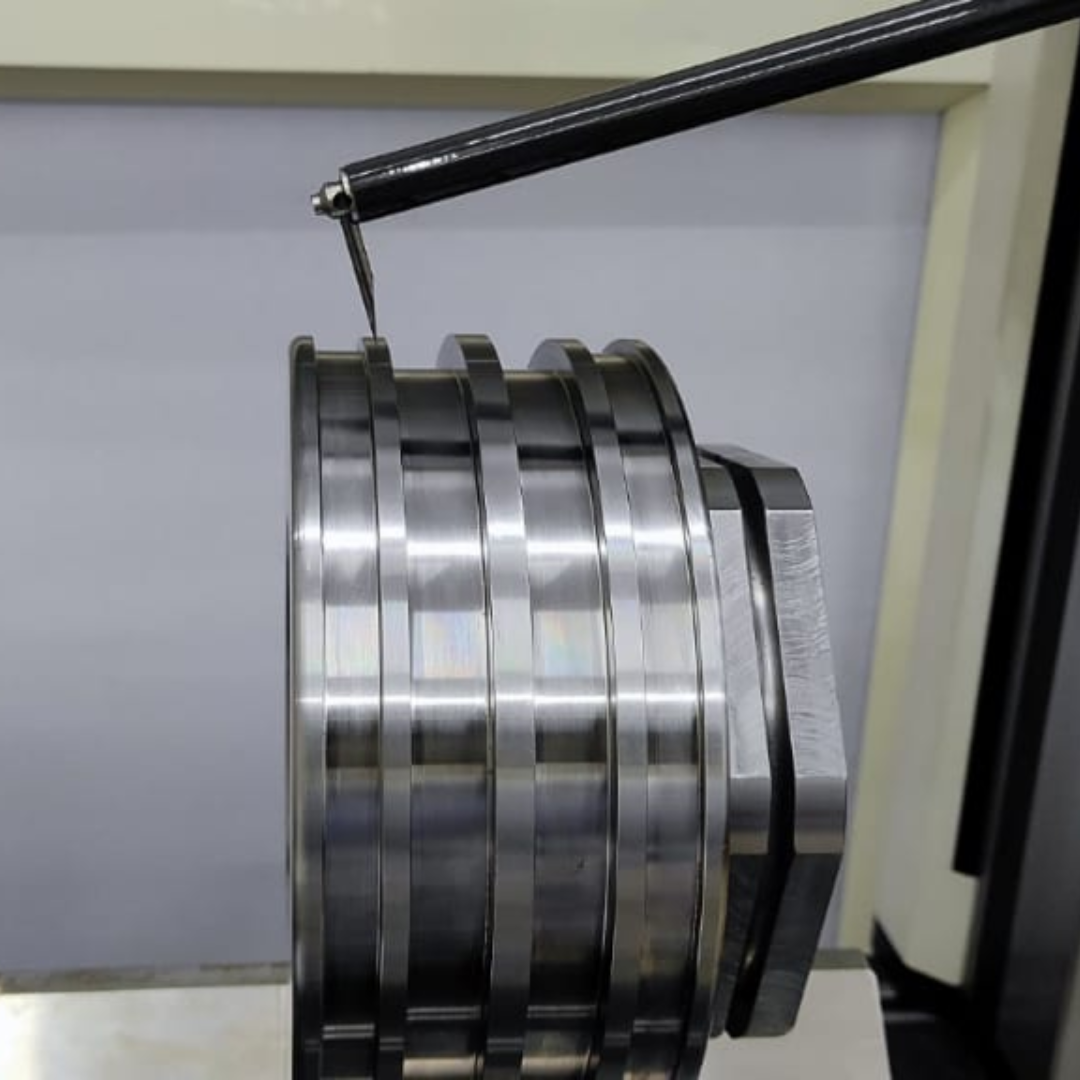

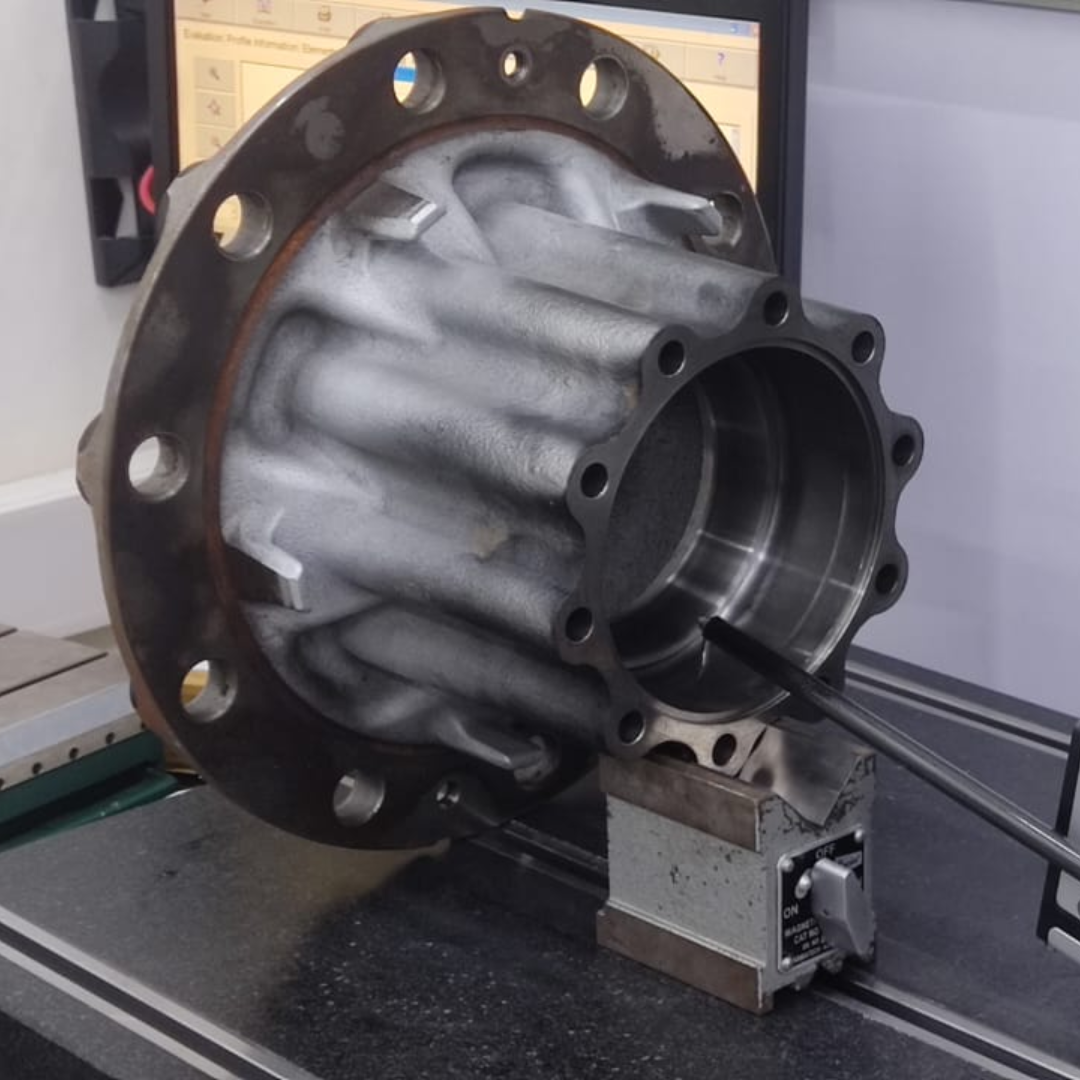

Our CMM (Coordinate Measuring Machine) inspection services help you verify your parts with the highest level of accuracy, powered by expert metrology solutions. Using the latest 3D CMM technology, Mapana ensures precise component measurements as an integral part of your Quality Assurance process.

Our Advanced CMM Equipment

Carl Zeiss Contura G2

- Measuring range: 700 x 1000 x 600 mm

- Volumetric accuracy: (1.8 + L/300) μm

- Capable of point-to-point and continuous measurement

- Full CAD model comparison

- Zeiss RDS articulating probe with up to 20,376 positions in 2.5° increments

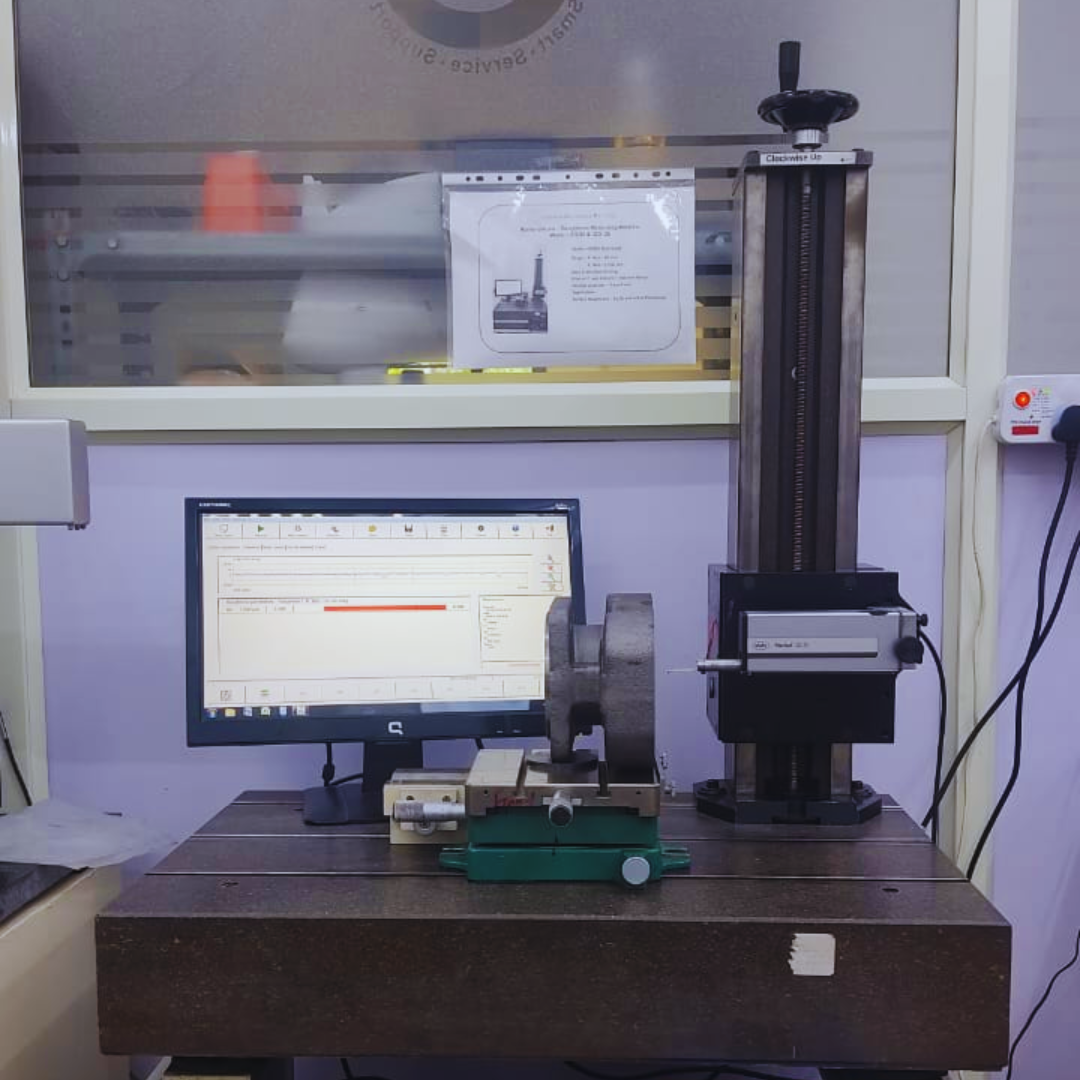

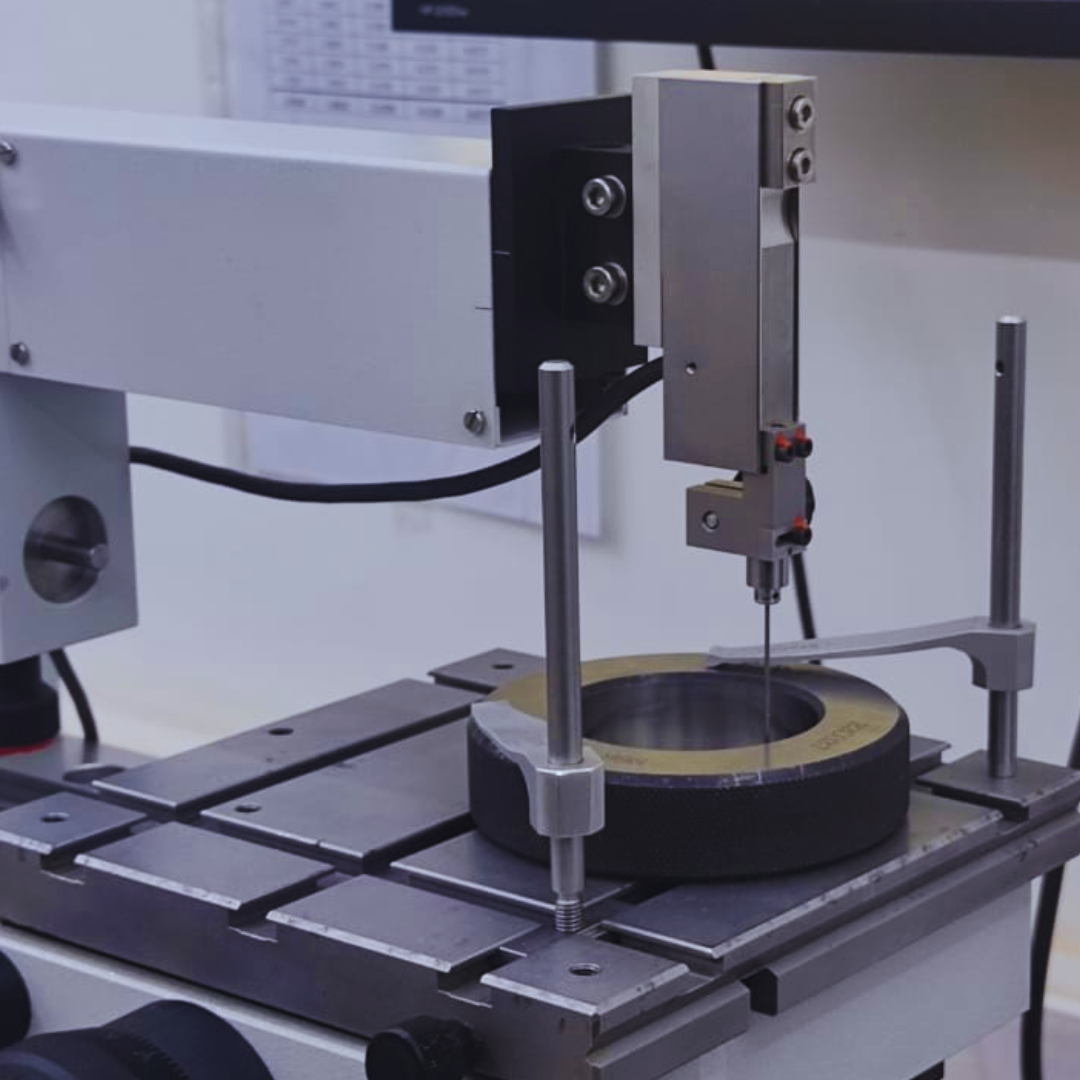

Contour Measurement Services

Our Contour Measurement Service enables you to accurately assess the 2D profile of your parts with high precision. We offer a wide range of stylus options, allowing us to adapt to various profile complexities. Depending on the part geometry, we can easily interchange stylus to ensure the best measurement results.

Our Equipment

We utilize the contour measuring instrument, delivering superior accuracy with the following specifications:

- Measuring Range: Granite plate: 700 mm × 550 mm (L × W) with three 10 mm T-grooves Motorized vertical adjustment: 500 mm range for the drive unit Traversing length (X): 0.2 mm to 120 mm Measuring range (Z): 50 mm (with 350 mm probe arm) / 25 mm (with 175 mm probe arm)

- Capabilities: Profile measurement Detailed dimensional reporting

- Specific Profile Measurements – Customized to your component requirement

- Programming on Customer Equipment – Including fixturing systems and operator training

- On-Site Programming – At your facility, using your equipment

Services We Offer:

3D Scanning Solutions

At Mapana Metrology Pvt Ltd we understand the critical demands of managing complex plants, storage tanks, and industrial assets. Our state-of-the-art 3D laser scanning services deliver the data accuracy you need to plan, inspect, maintain, and comply—efficiently and confidently.

What We Deliver

- Traceable 3D Models & Drawings – High-fidelity digital models that streamline inspection planning and documentation.

- 2D-to-3D Conversion – Transform outdated drawings into accurate, intelligent 3D data to reduce rework, errors, and project delays.

- Complete 3D Documentation – Support troubleshooting, maintenance planning, and regulatory compliance with comprehensive digital records.

- Reduced Downtime – Fast scanning workflows help you shorten maintenance windows and avoid unplanned shutdowns.

Vision Measuring Machine

VMM (Vision Measuring Machine) inspection services utilize optical systems to measure and analyze parts, offering a non-contact measurement method for quality control. These services are commonly used in manufacturing to ensure dimensional accuracy and consistency of products.

- High-resolution images: VMMs use high-resolution cameras to capture detailed images of parts.

- Intuitive software: Specialized software allows users to analyze images, make measurements, and generate reports.

- Precision mechanics: VMMs incorporate precise mechanical platforms to ensure accurate positioning of the part during inspection.

- Versatility: VMMs can be used for a wide range of parts, from small, intricate components to larger parts.

- Data analysis and reporting: The software can generate reports with measurement data, which can be used for quality control and process improvement.

Key features and benefits:

Examples of VMM inspection applications:

- Checking dimensions of machined parts: Ensuring parts meet specifications and tolerances.

- Analyzing the shape and profile of components: Verifying that parts conform to design requirements.

- Measuring the position of features on a part: Ensuring correct alignment and assembly.

- Performing pre-shipment inspections: Verifying product quality before dispatch.

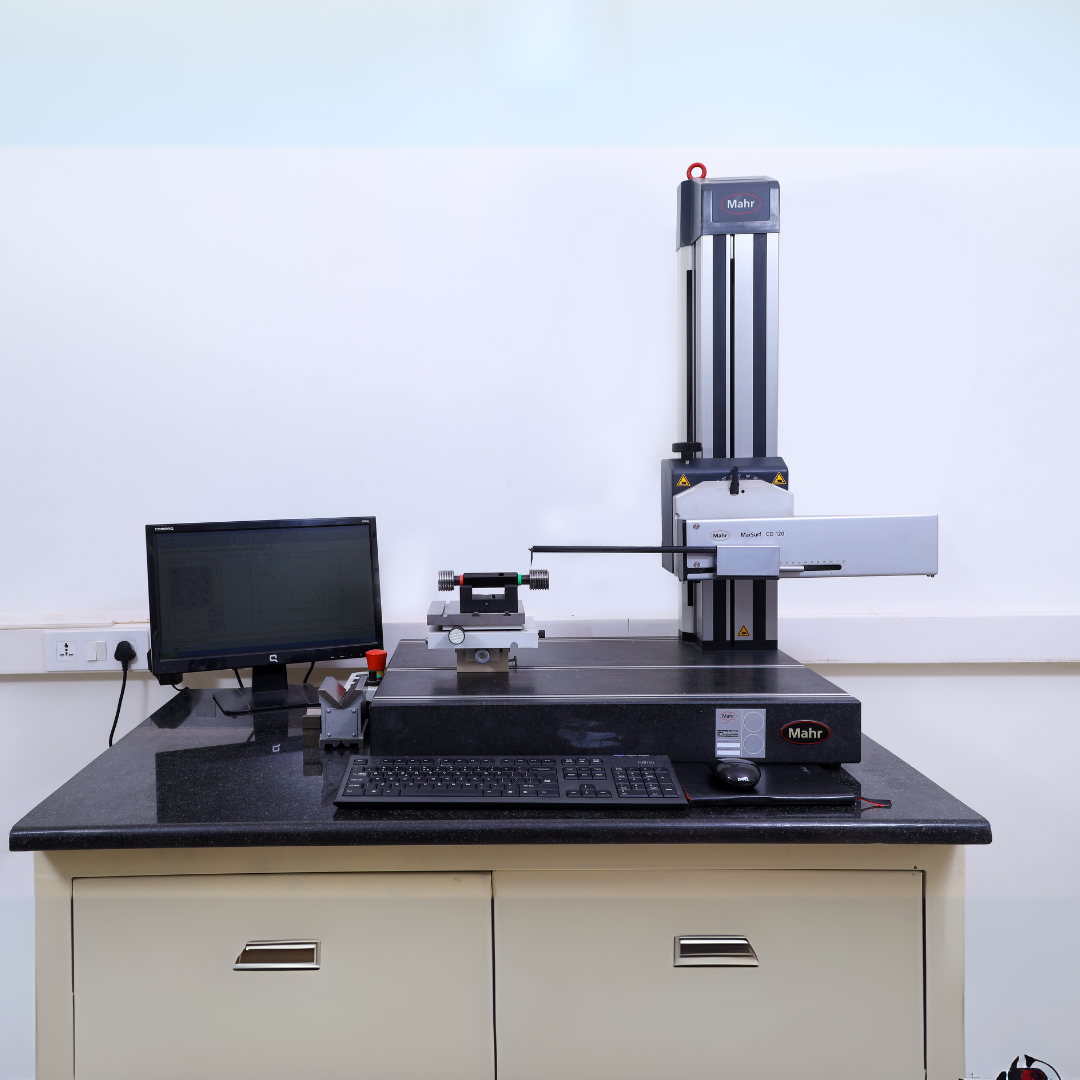

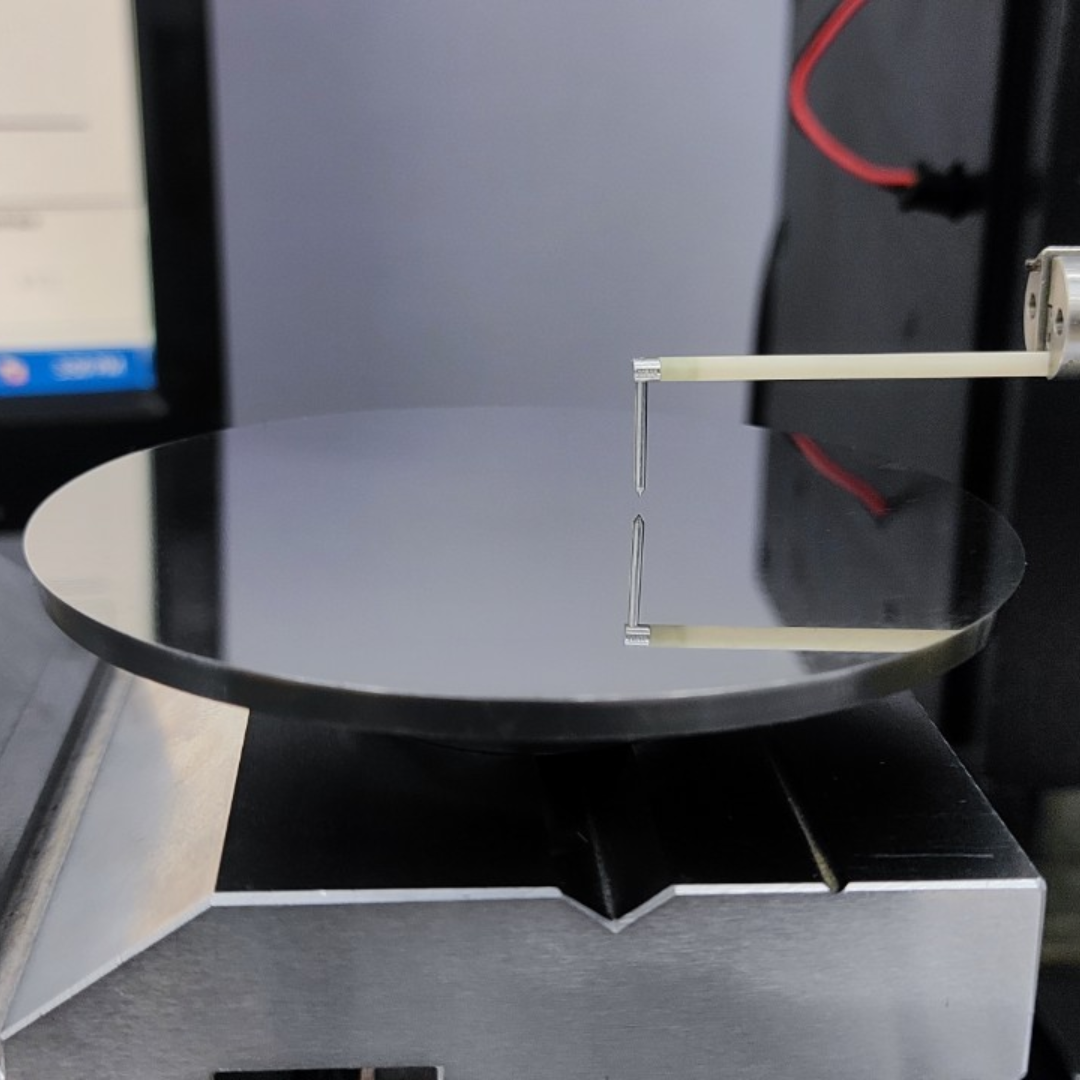

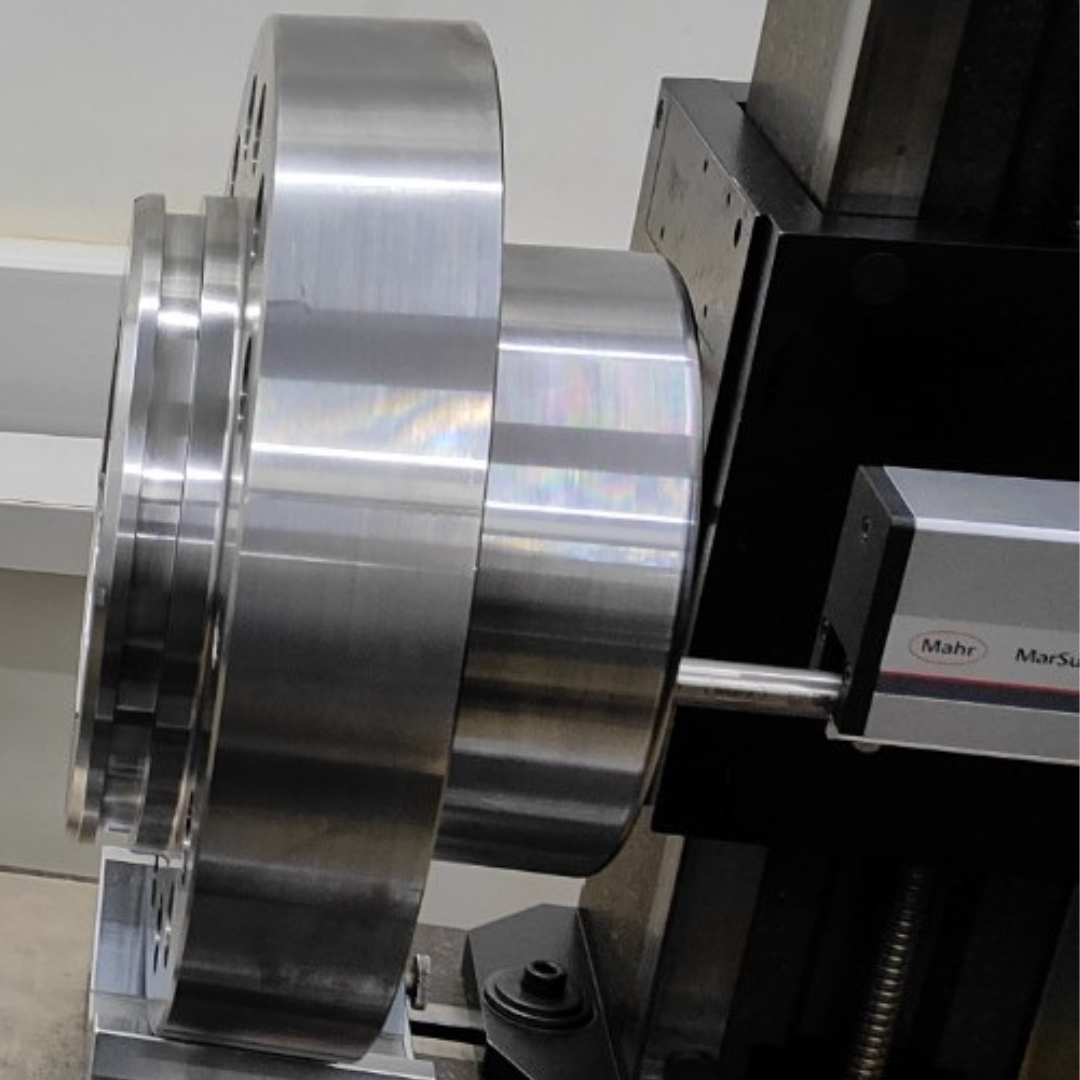

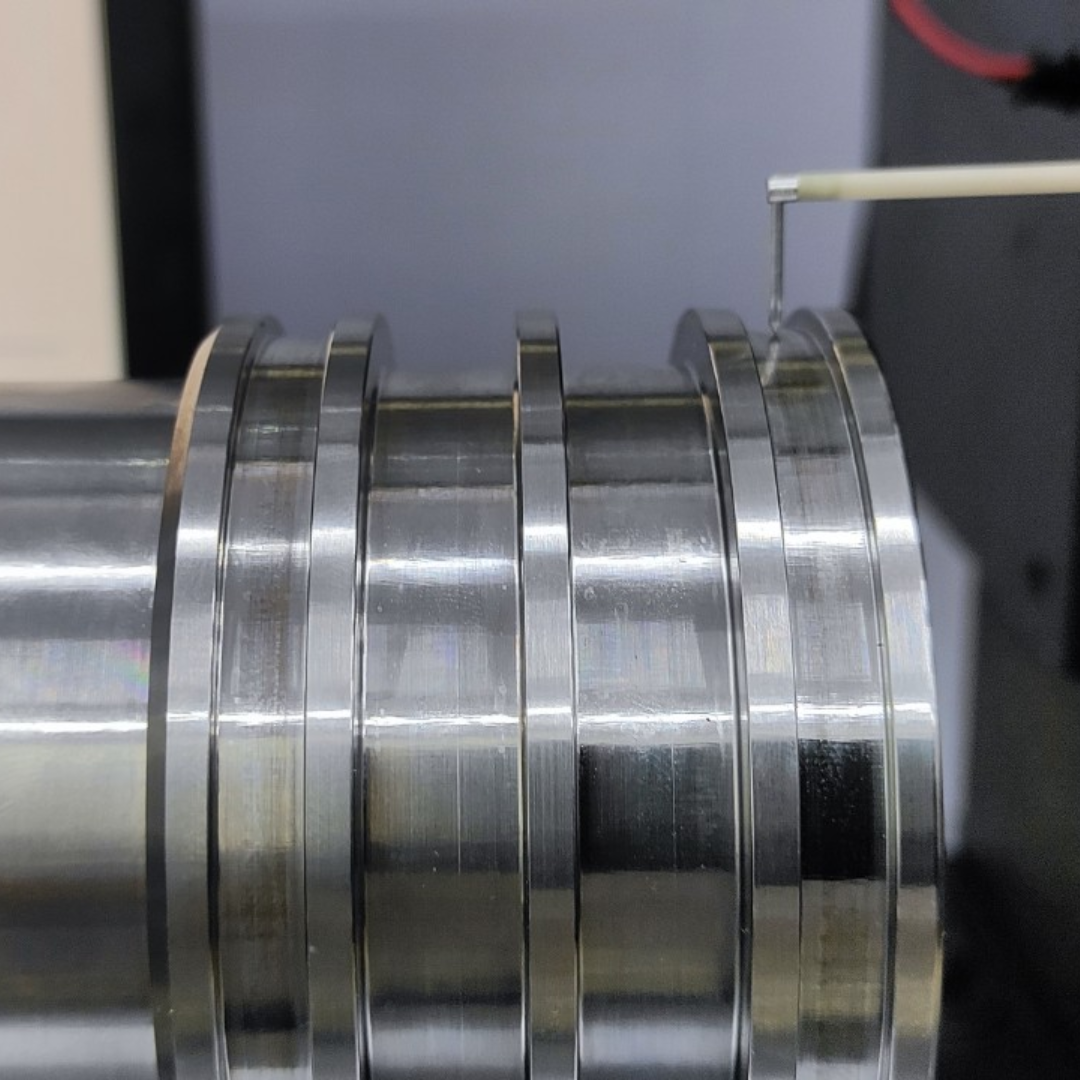

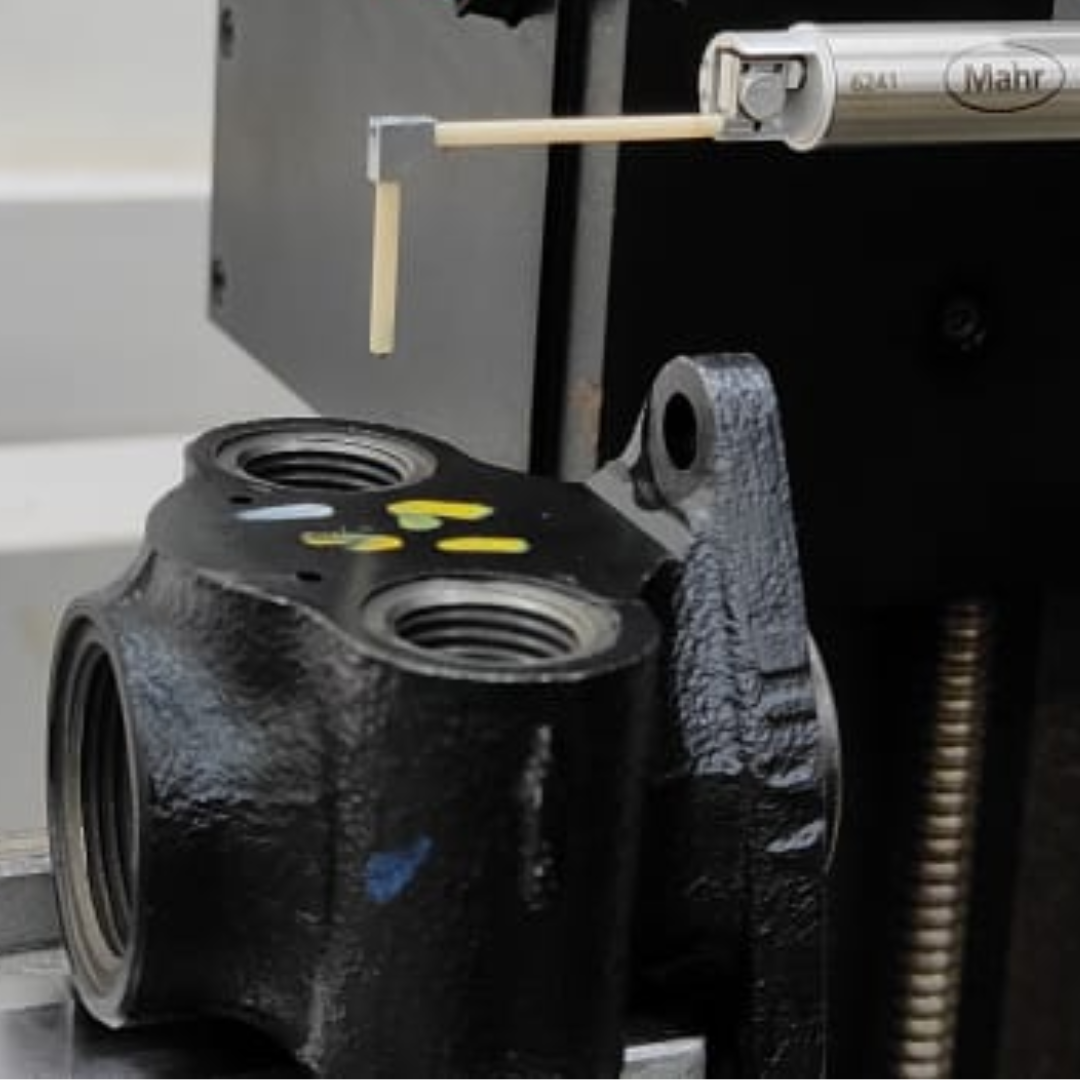

Surface Roughness Measurement Services

Mapana Metrology provides advanced Surface Roughness Measurement services to evaluate the quality and performance of your machined components. Our inspection ensures flatness accuracy and helps detect surface defects or irregularities that may impact functionality.

We can assess roughness and waviness levels on virtually any type of surface, including:

- Flat surfaces

- Deep grooves

- Small holes

- Crankshaft axes

- Gear flanks, and more

Our Equipment Roughness Tester

we ensure precise and reliable surface evaluation. Key specifications include:GD 25 Drive Unit – Accurate measurements up to 25 mm traversing length Z-axis Measuring Range: Skidless Pickup: ± 250 μm With double-length tracing arm: ± 500 μm

- Roughness profile

- Waviness profile

- Primary profile

- Evaluation of geometric characteristics

- Measurements according to multiple international standards

- Comprehensive dimensional reports

Capabilities:

Our Services Include:

- Customized roughness measurements based on specific requirements

- Expert consultation on roughness parameters and standards

- Measurement of inaccessible areas using replica techniques (resins), allowing extraction and analysis of surface finish indirectly

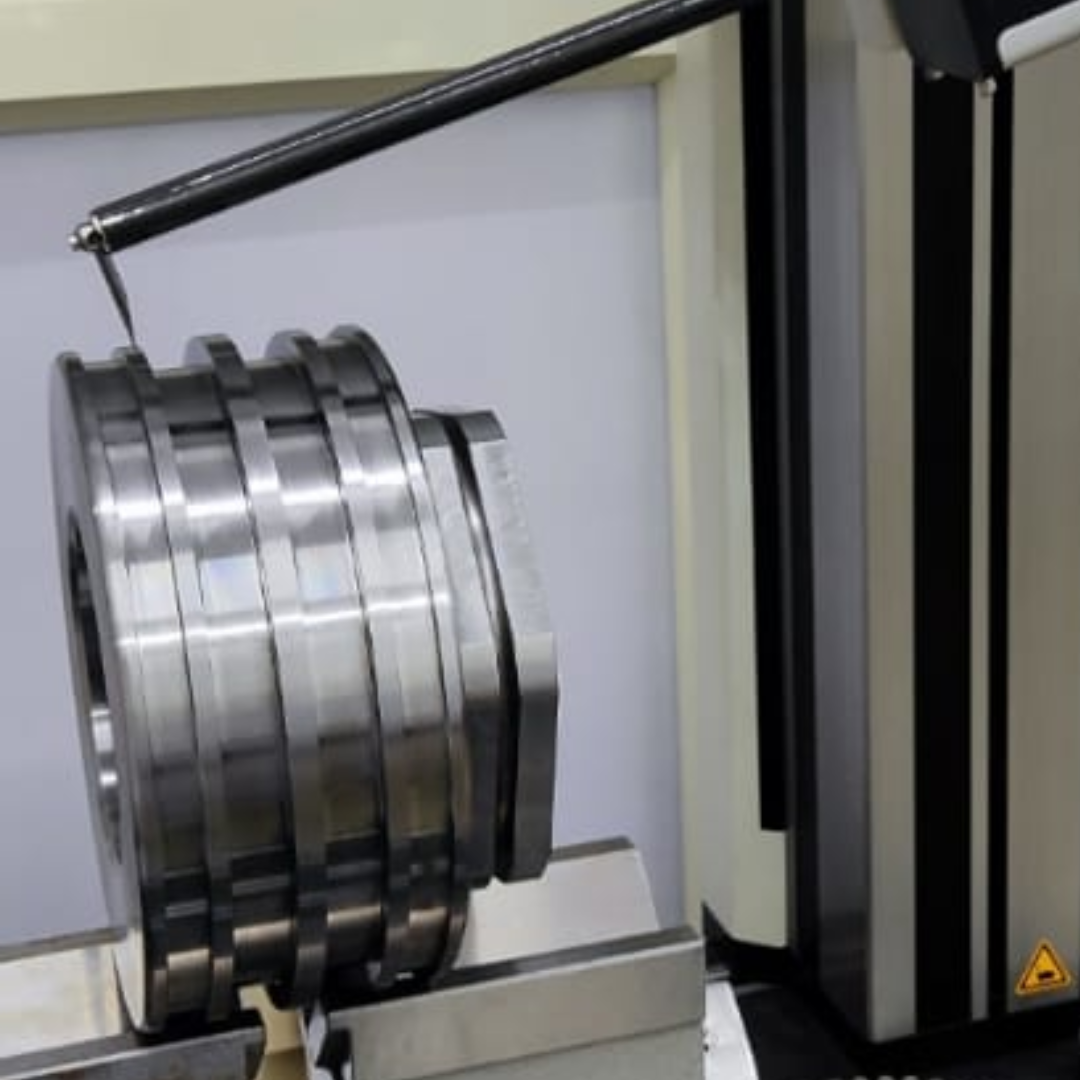

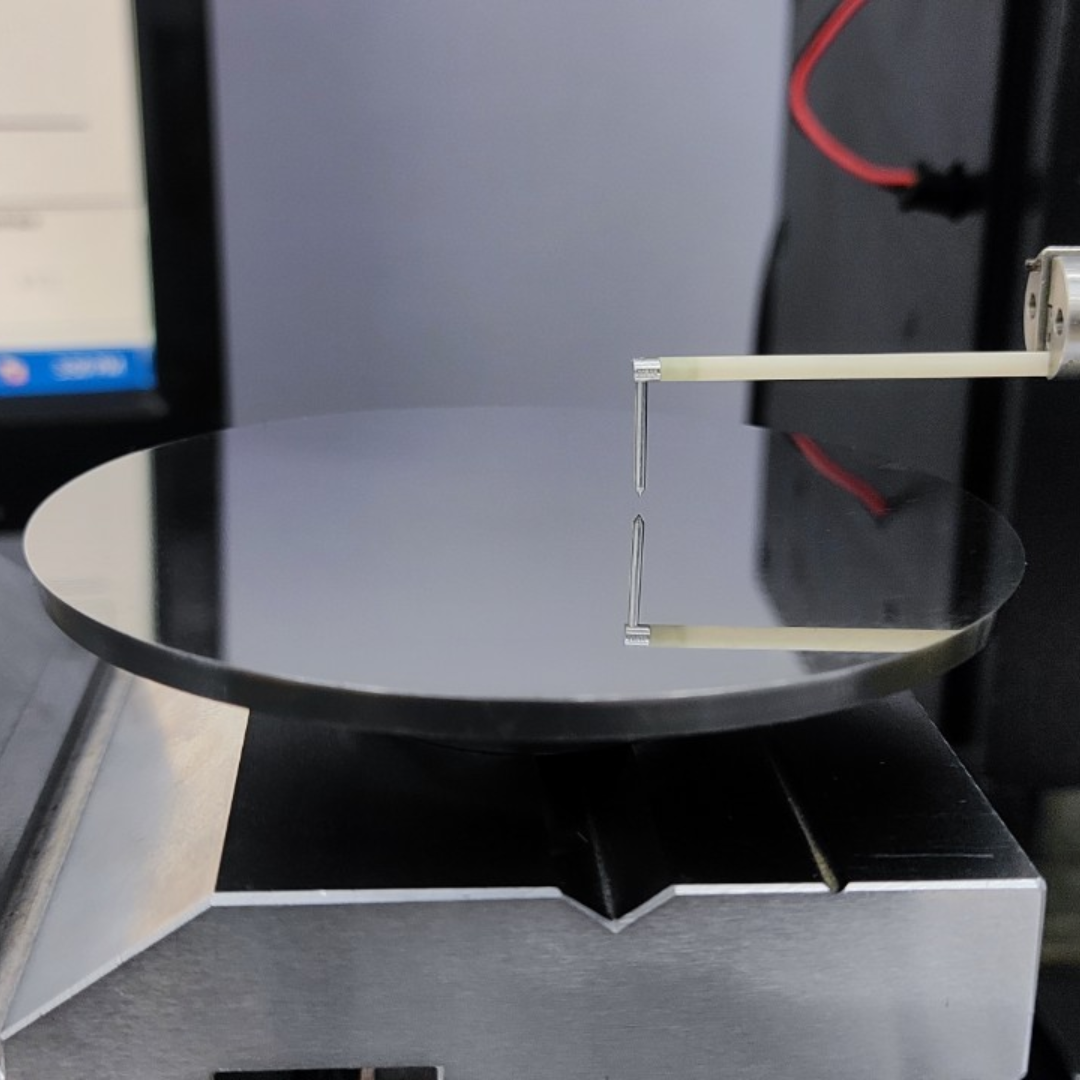

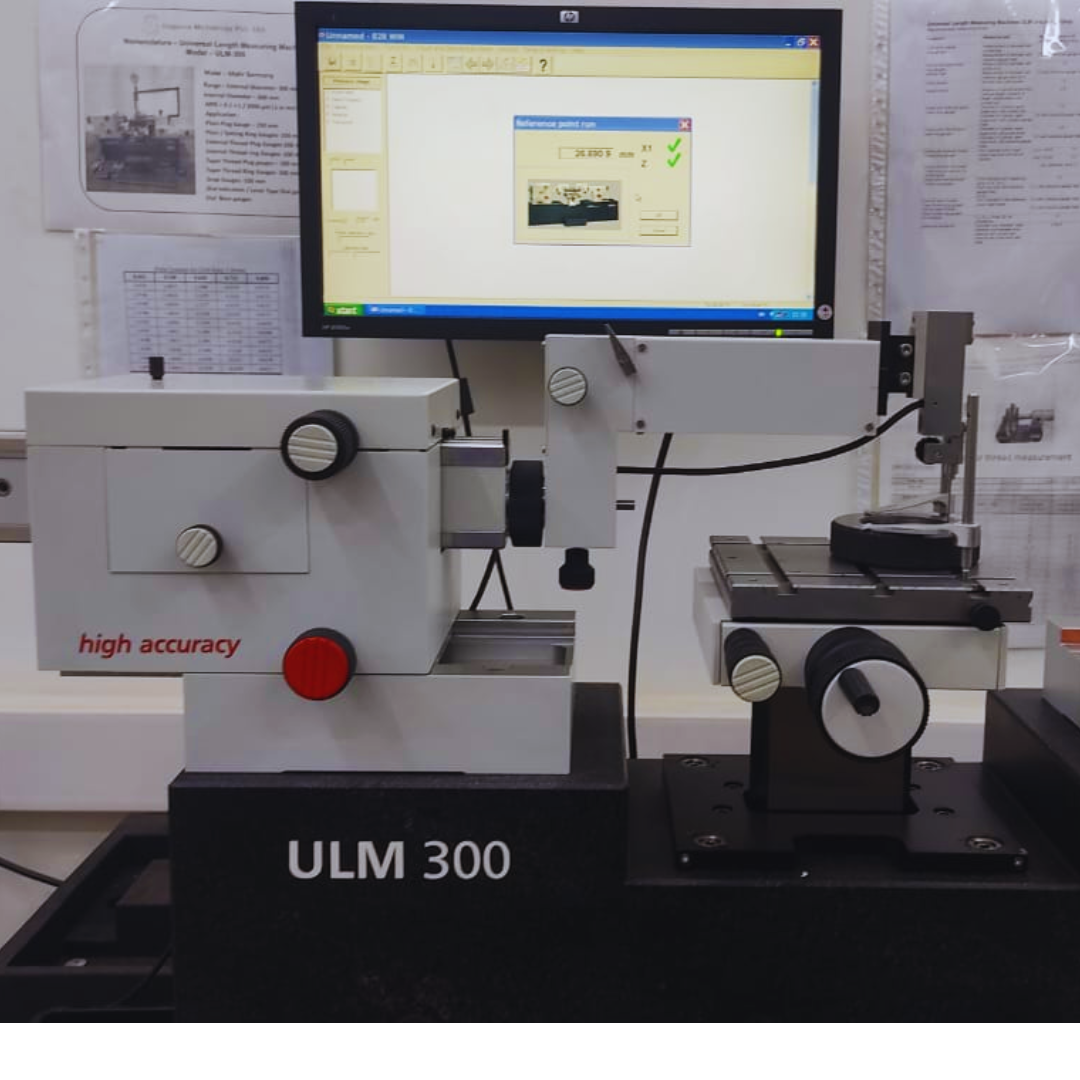

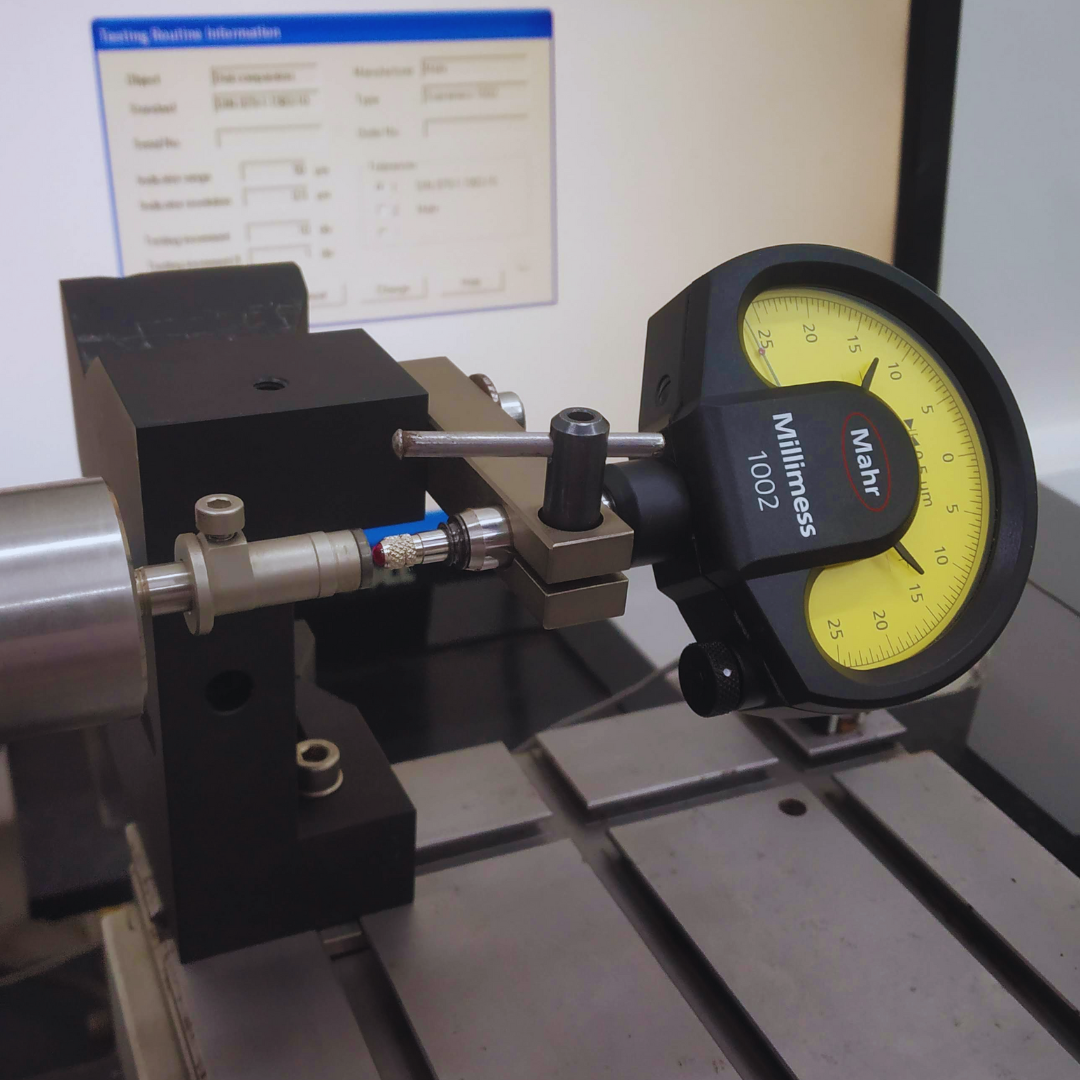

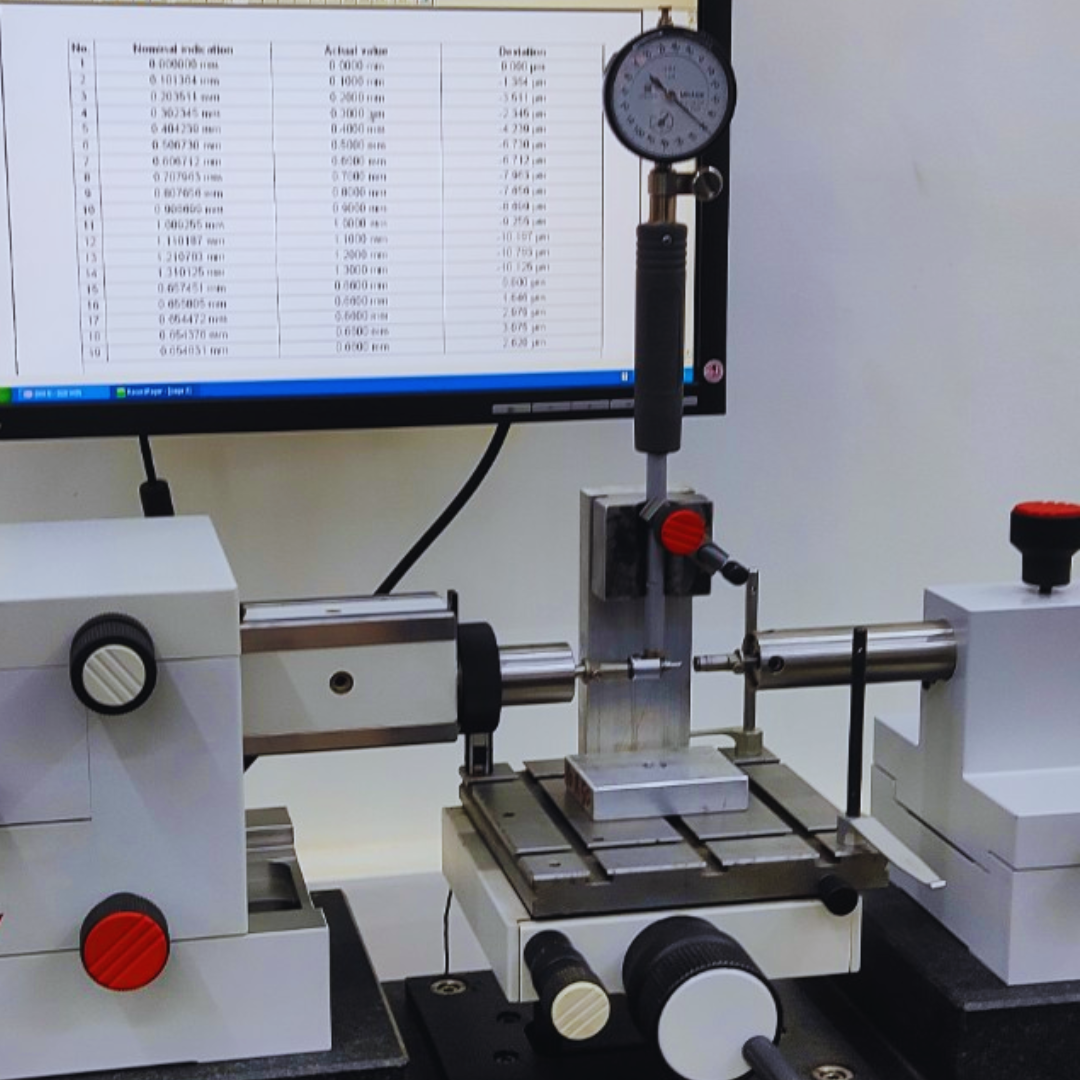

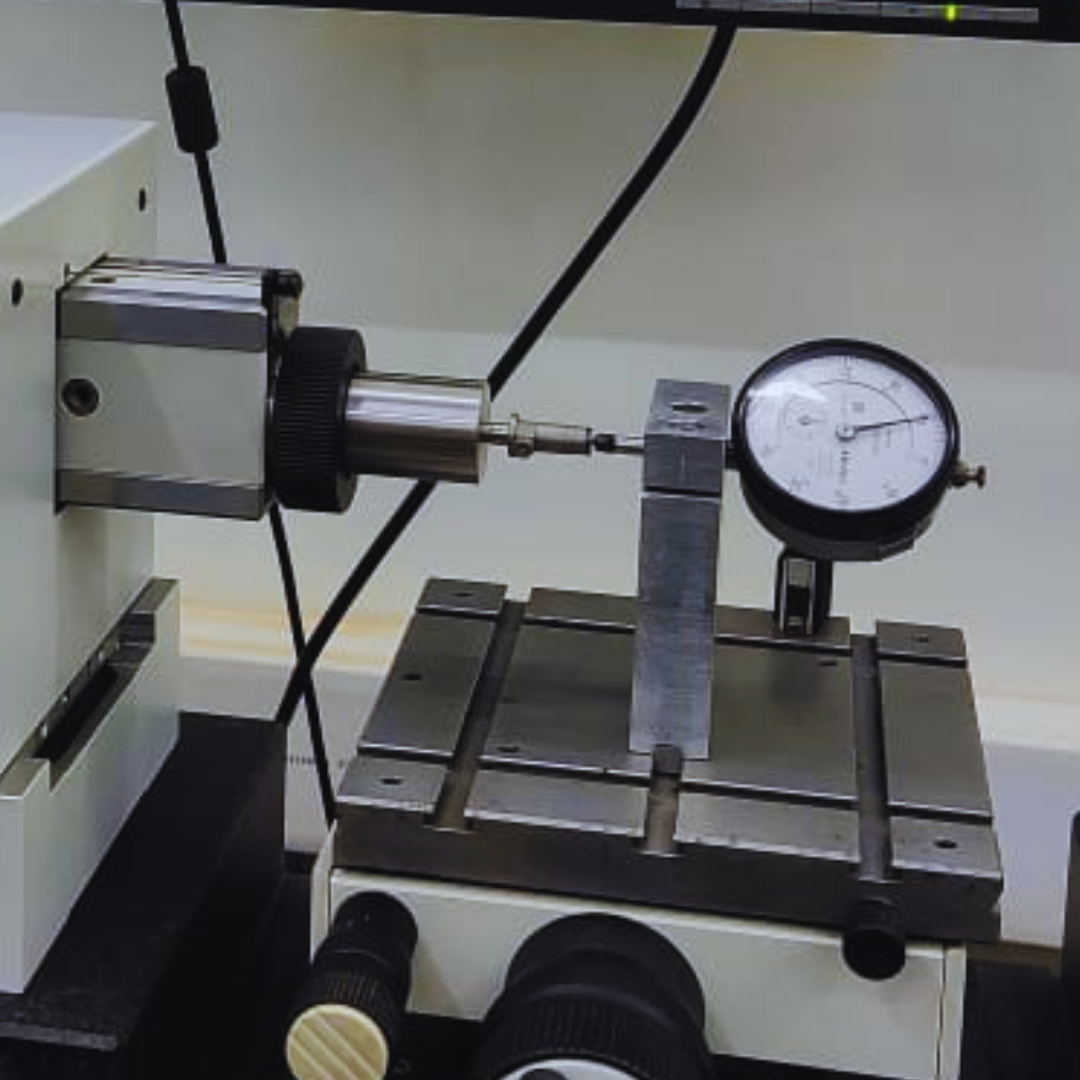

Universal Length Measuring Machine

Model: ULM-300 Measuring Range:

- External Diameter: up to 300 mm

- Internal Diameter: up to 260 mm Accuracy: MPE = (0.1 + L / 2000) μm (where L = length in mm)

Applications:

- Plain Plug Gauges: up to 150 mm

- Plain/Master Setting Ring Gauges: up to 150 mm

- External Thread Plug Gauges: up to 100 mm

- Internal Thread Ring Gauges: up to 100 mm

- Taper Thread Plug Gauges: up to 100 mm

- Taper Thread Ring Gauges: up to 100 mm

- Snap Gauges: up to 150 mm

- Dial Indicators, Lever-Type Dial Gauges, Probes, Dial Bore Gauges

Technical Features & Advantages

The Universal Length Measuring Machine (ULM) is considered the benchmark instrument for certifying precision instruments and gauges in industrial metrology. Mapana Metrology Pvt. Ltd. proudly houses this critical high-accuracy machine, offering MPE of 0.1 + L / 2000 μm, making it ideal for linear dimensional measurements in quality assurance environments. Key

- Active Temperature Sensors & Compensation – Ensures consistent accuracy under varying conditions

- Rigid Granite Base Construction – Built on the ABBE principle for ultimate measurement reliability

- Primary profile

- High Precision Applications – Suitable for components such as gears, journals, ball hubs, cages, rings, tapers, gear shafts, and for calibration of gauges & test equipment

- Modular Design – A wide range of accessories and components are available, enabling future expansions and customization

- Comprehensive dimensional reports

characteristics:

Our Services Include:

- Customized roughness measurements based on specific requirements

- Expert consultation on roughness parameters and standards

- Measurement of inaccessible areas using replica techniques (resins), allowing extraction and analysis of surface finish indirectly

Retrofit Service

With over 25 years of expertise in installation, training, repair, maintenance, consultation, and retrofit of dimensional measurement equipment, we specialize in maximizing the potential of your existing machines. By upgrading them with the latest probes, advanced software, and state-of-the-art electronics, we transform your legacy systems into modern, high-performance measuring equipment.

Regardless of the kinematic design of your CMM—movable bridge, fixed bridge, cantilever, horizontal arm, or gantry—we thoroughly assess its structure. Through precise modifications or optimization of the reading system, we adapt and configure it to deliver the accuracy, reliability, and performance of updated equipment.

Metrology Training

At Mapana Metrology, we believe that the success of any technological investment depends on the specialized training of its future users. To ensure this, we have developed a comprehensive theoretical and practical training methodology designed to help participants achieve maximum performance from day one.

Training Programs

Entry-Level Training At this stage, users acquire essential measurement and programming skills to operate their system effectively.

Advanced Training & Consulting This level provides personalized consulting and advanced training tailored to each user’s specific challenges, ensuring they gain practical solutions for their unique applications.

Customized Programming Training Companies can opt for on-site, project-specific training, where our experts supervise and guide the programming of actual parts to guarantee optimal results.

Engineering & Projects

In-line metrology provides the sense and the point of conciliation between quality and production within the shop floor; it ceases to be a final sentence on a planned and finished production activity and becomes a means of control that provides reliability and assurance to the processes, adjusting to the cycle times that production sets us. To carry out the control at the source avoiding the generation of the error, with the objective of manufacturing "zero defects" or in that process in which the error occurs, it allows to identify the cause that provokes it and to be able to correct it before it passes to the next phase.

Your challenges are our challenges

- Guarantee cycle times of the production line

- Develop multi-reference turnkey projects- With minimum investment in tooling - With a single configuration of probes for all references

- Delivery of bulk parts, automatic recognition for loading on measuring equipment